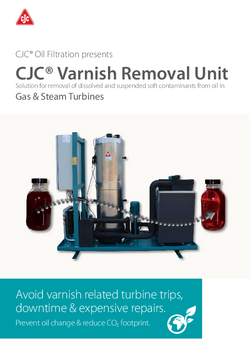

varnish removal insert, VRI

Specially designed for removal of dissolved varnish in hydraulic and turbine oils

The CJC® Varnish Removal insert, VRi 27/27, is used in the CJC® Varnish Removal Unit, VRU. The VRU contains 4 x VRi 27/27 Filter Inserts, which are specially designed for efficient removal of dissolved and suspended soft contaminants from turbine lube and hydraulic oils that operate at continuously high temperatures.

Used for the maintenance of the below applications:

- Gas turbines

- Steam turbines

- Compressors

- Hydraulic systems

- Generators

- Gearboxes

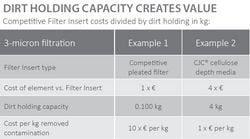

Contamination Capacities:

Based on field experience we have observed that the total Dirt Holding Capacity (DHC) is dependent on the shape and density of particles and other variables within an oil system.

Documented cases have shown the removal of 4 kg (4,000 g)/8 lb of solid contaminants and oil degradation products per filter insert with one VRU Filter Insert change (4 x VRi 27/27 16 kg/32 lb). Single-pass efficiency for varnish removal and MPC reduction of up to 99 percent. An Ultra-Centrifuge test can also be used to detect varnish.

Your benefits with CJC®

CJC® Filter Inserts have the highest dirt holding capacity on the market due to special cellulose-based material. Furthermore, the unique construction of the bonded discs, creates a large filtration area resulting in reduced costs of ownership. The CJC® Filter Inserts are a modular design, which allows them to fit any applications and requirements.

- The CJC® Filter Insert features:

- Depth media of moulded cellulose

- Highest Contamination Capacities (DHC)

- 100% natural cellulose fibres from sustainable resources;

no plastic, no metal, no chemical

- Removal of contaminants, 4-in-1:

- Particles:

Lifetime of both oil and component are increased considerably. - Oil degradation products:

Avoid sticking valves, lacquering, and varnish on metal surfaces. - Water:

Reduce the risk of micro-pitting, bacterial growth, sludge etc. - Acidity/TAN:

Reduce oil ageing and wear on equipment.

- Particles:

- OEM requirements

Experience and application knowledge of C.C.JENSEN ensure that CJC® solutions can meet specifications from OEMs on oil cleanliness.

How to ensure Clean & Dry oil

Remember to change CJC® Filter Inserts according to pressure gauge or at least once a year in order to ensure clean & dry oil! - Click here to learn how to replace a CJC® Filter Insert.

Learn how other customers benefit with CJC® – Click to download Customer Cases.

- ALSTOM-Gas-Turbine-GT8C2_Turbine-Oil, Combined-Heat-and-Power-Plant_ASIN5146

- Gas & Steam Turbine GE 109FA, Lube & Hydraulic Oil, Combined Cycle Single Shaft_CCPO6050

- Gas Turbine GE40MW, Lube Oil_Cogeneration Plant_CCPO6052

- Gas Turbine, GE 6FA+e, Bearing, Load Gear & Control, Turbine Oil, Rusal Aughinish Alumina, Irland, ASPO6047UK

- Gas Turbine_2xGE 84 MW_CCCP Power Plant_Turbine Oil_Energyworks Cartagena Iberdrola_ASIN5132

- Gas Turbine_GE 7FA-300 MW_CCGT Power Plant_Turbine Oil_Combined-Cycle Generation USA_ASIN5133

- Gas Turbine_GE-LM6000_Generator Bearings & Gearbox_Turbine Oil_Energyworks Valladolid_ASIN5141

- Power Plant USA_Lube & Control Oil, Combined Cycle-Natural Gas Turbine, GE7FA_ASPO6048

- Urban Waste Management Plant_Steam Turbine, Lube Oil, Siemens SST-400,65 MW_ASPO6051