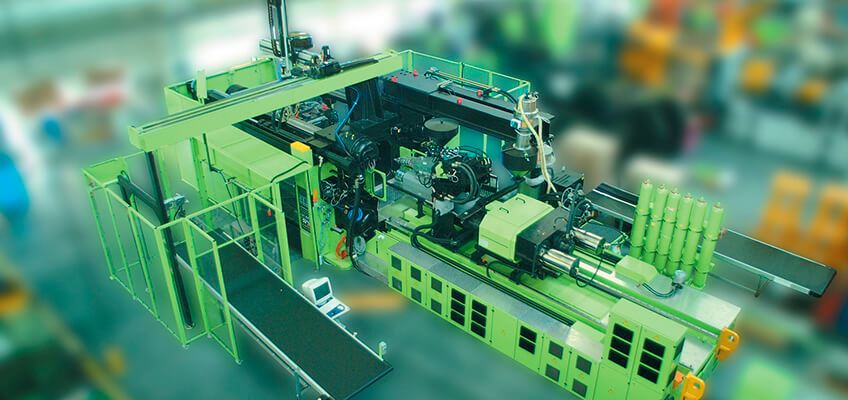

plastic moulding

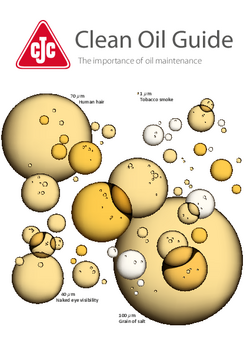

Plastic moulding machines are highly complex production machines, and reliable equipment is the key to maintaining a high output of finished goods. A wide range of hydraulic components, such as pumps and proportional valves are used to make the plastic moulding machine perform to it's optimum. The small tolerances between components in the hydraulic system make it critical to keep the oil clean and dry, and free from oxidation residues.

Challenge

Relying solely on in-line filters in plastic moulding machine is a high risk strategy. In doing so, the hydraulic system risks being subjected to many particles in varying size that can lead to expensive downtime, loss of efficiency in production output and lower quality products. If the oil in the hydraulic system is not clean, then you risk extra wear on the hydraulic components and unplanned breakdowns in production. If you do not keep the oil free from oxidation residues, then you risk much shorter lifetime of the oil and sticking valves during start-up. All lead to increased downtime and higher cost of operation.

Benefits, installing CJC® Oil Filters

- Keeps your plastic moulding machines fit for operation

- Maintain high process stability and efficiency

- Reduce risk of unplanned breakdowns and maintenance

- Ensures long lifetime of expensive hydraulic system components

- Extend hydraulic oil lifetime with a factor 3-4

When you install a CJC® Oil Filter solution on your plastic moulding machine, you get a very effective oil filter with the highest dirt capacity suitable for system with high levels of particles or oxidation residues. This way you do not need to stop production untimely to service the oil filter. Technically, CJC® Oil Filter is known for keeping oil clean, dry and without oxidation residues, which is documented over many years and in numerous plastics production installations. When you choose CJC® Oil Filter, you ensure a long lifetime of the hydraulic components, reduce maintenance costs and avoid unplanned breakdowns. Hydraulic oil lifetime can be extended with a factor 3-4, and you can even monitor from the central monitoring location the condition of your system using the Oil Contamination Monitor (OCM).

Your solutions

Many sizes of CJC® Oil Filters are used for the plastic molding industry:

- Fine Filters from size HDU 15/12 up to HDU 27/108 series

- Oil Contamination Monitor, OCM15

The CJC® System Solutions fit all hydraulic plastic moulding machines, and we can deliver globally where required. In close co-operation with technical organizations, we help select the most fitting solution depending on system type and conditions in the environment.

Learn how other customers benefit with CJC® – Click to download Customer Cases.

- Plastic Extrusion Machine_SCHEIDER_Gear / Bearing Oil_Cork Plastics_ASIN5089

- Plastic Injection Moulder_BILLION_Hydr Oil_Neyr Plastiques_ASIN5073

- Plastic Injection Moulder_BILLION_Hydr Oil_Novaes_CCIN5073

- Plastic Injection Moulder_ENGEL Battenfeld & Ferromatic Milacron_Hydr Oil_ASIN5016

- Plastic Injection Moulder_ENGEL-STORK ST4000-550_Hydr Oil_DPI Dielco_ASIN5046

- Plastic Injection Moulder_KRAUS MAFFEI KM 150-700_Hydr Oil_Bic Violex_ASIN5015

- Plastic Injection Moulder_PONAR ZYWIEC_Hydraulic Oil_ZMM Maxpol_ASIN5057

- Plastic Injection Moulder_STORK SX 3000/2100_Hydr Oil_Wavin Metalplast_ASIN5017

- Plastic Injection Moulder_STORK_Hydraulic Oil_Bianor_ASIN5079

- Plastic Moulding Machine_ENGEL_Hydraulic Oil_DBI Plastics_ASIN5088