bearings

System

The predominant bearing type in wind turbines are SRB (spherical roller bearings), both in the gear and the main bearing. The main bearing is either grease or oil lubricated. In the oil lubricated main bearings, it has until now not been common practice to filter the oil, but doing so makes good sense. In grease lubricated bearings, the grease holds on to contaminants and it is impossible to clean the grease. This reduces the lifetime of the bearings, making oil lubricated bearings more and more popular.

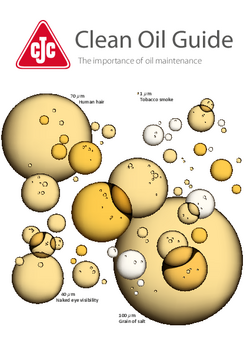

Regardless of lubrication type, bearings remain a complex mechanical structure, with high loads and small clearances and despite best efforts, they sometimes fail. The latest design revolution is the introduction of journal bearings in the GBX. This new feature, despite being less complex, actually requires higher levels of cleanliness, especially during start/stop conditions. Optimising bearing conditions provides for the best conversion of rotor-to-generator power, which optimizes the output of the turbine.

Challenge

If particles, moisture and varnish are not continuously removed from the bearing lube oil, you risk very expensive repairs or replacements of the large bearings. Because of the immense dynamic pressure on the bearings, wear particles will be released, giving less lubricity and higher friction losses thus optimum yield cannot be achieved. Energy is simply wasted in the process. Downtime during repairs is extensive and penalties for not delivering power to the grid may be incurred, similar to when a gearbox breaks down.

Benefits, installing CJC® Oil Filters

- Protect your investment and ensure long lifetime of bearings

- Optimize availability and output

- Reduce risk of expensive bearing failure or replacement

- Reduce risk of unplanned breakdowns and maintenance

When you install a CJC® Offline Oil Filter solution on your wind turbine bearings, you get an oil filter that removes fine particles, moisture and varnish effectively. Technically, CJC® is known for keeping bearing lubrication oil clean and dry and without oxidation residues. This is documented over many years and in several thousand similar installations. When you choose the CJC® Offline Oil Filter, you ensure a long lifetime of the expensive bearings, reduce maintenance and you avoid unplanned breakdowns. You can even remotely monitor the condition of your system using the Oil Contamination Monitor, OCM15.

Your solutions

For wind turbine main bearings, the following CJC® Oil Filter solutions apply:

- Oil Filter, Key Filter

- Oil Filter, HDU 15/25

- Filter insert, BG 15/25

- Oil Contamination Monitor, OCM15

The CJC® system solutions fit the growing size of the wind turbines, and we can deliver customised and OEM branded filter inserts as required. In close co-operation with technical organizations, we help select the best solution depending on turbine type and environmental conditions.