cement industry

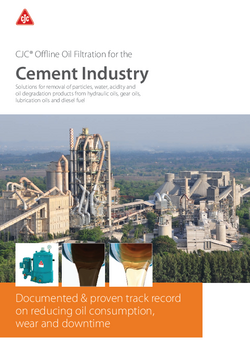

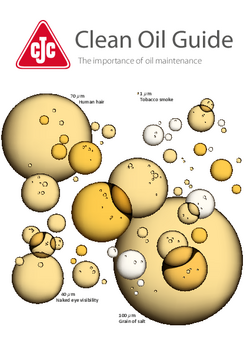

Cement plants are complex production plants in rough environments, and reliable equipment is the key to maintaining a high output. A wide range of sub-systems like crushers, mills and the rotary kiln have to run constantly and be free from unnecessary production stops. Due to the high temperature and high amount of dust in the environment, it is critical to remove all oxidation residues and to keep the oil clean and dry.

Challenge

If the complex and varied systems are not running at their optimum, you risk expensive down time, loss of efficiency in the supply chain and lower output. Gearboxes, bearings and hydraulic components are wearing with moisture and particles in the oil that can lead to unplanned breakdown, and the need to acquire valuable spares with long lead times.

Benefits, installing CJC® Oil Filters

- Maintain high process stability and output

- Reduce risk of unplanned breakdowns and maintenance

- Reduce maintenance cost, by extending lifetime of bearings, pumps, etc.

- Extend lubrication oil lifetime with a factor 3-4

When you install CJC® Oil Filter solutions on your cement plant, you get a very effective oil filter with the highest dirt capacity suitable for system with high levels of particles or oxidation residues. This way you do not need to stop production untimely to service the oil filter. Technically, CJC® Oil Filter is known for keeping oil clean, dry and without oxidation residues, which is documented over many years and in several cement production installations. When you choose CJC® Oil Filter, you ensure a long lifetime of pumps, gearboxes, bearings and hydraulic components. You also reduce maintenance costs and avoid unplanned breakdowns and lubrication oil lifetime can be extended with a factor 3-4. You can even monitor the condition of your system oil cleanliness using the Oil Contamination Monitor, OCM15.

Your solutions

Many sizes of CJC® Oil Filters are used for the cement industry:

- Fine Filters from size HDU 27/27 up to large multi-stay HDU 27/108 series and HDU 427/108

- Filter Separators from size PTU2 27/27 up to PTU 27/108

- Oil Contamination Monitor, OCM15

The CJC® system solutions fit all oil systems within the cement plant, and we can deliver globally where required. In close co-operation with technical organizations, we help select the best solution depending on system type and conditions.

Learn how other customers benefit with CJC® – Click to download Customer Cases.

- Cement Mill Gearbox_Gear Oil_Blue Circle_ASIN5001

- Cement Mill, Finish Grinding Mill (FGM) Gearbox, Gear Oil, Lafarge Republic Inc. Philippines, ASIN5161

- Cement Mill, Main Gearbox, Gear Oil, Portlandzementwerk Wittekind Hugo Miebach Söhne, ASIN5156

- Cement Mill, Trunnion Bearings, Fixed & Floating, Lube Oil, Cement Plant in Ireland, ASIN5159

- Cement Mill, Vertical Raw Mill, Hydraulic Oil, Holcim Philippines Inc. Bulacan Plant, ASIN5160

- Cement Mill_Oven Gear FLS TD1500_Gear Oil_Aalborg Portland_ASIN5002

- Cement Mill_Rotary Kiln Trunion Bearing_Lube Oil_Golden Bay Cement_ASIN5118

- Coal Mill, Gearbox, MAAG Gear type WPU-27/C, Gear Oil, Ireland, ASIN5158