storage tanks

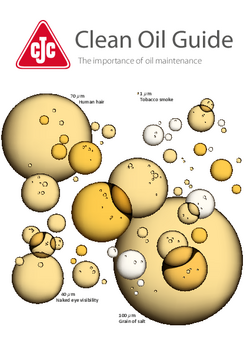

Every diesel storage tank is designed for and installed on a particular site, since the infrastructure varies a lot form mine to mine. Whether the tank is an on-site day tank, a combined storage and day tank or a terminal facility, they all face the same problem with diesel. Diesel is rarely delivered on site at a quality suitable to dispense straight into the equipment, forcing operators to filter the diesel before use. OEM recommendations today specify diesel at ISO codes 17/15/13, but injector manufactures say 12/10/8 if you want maximum lifetime of the equipment. Water is often present in diesel – either delivered with the supply, or as a result of condensation. Presence of water means diesel deteriorates after only few weeks in the tanks.

Challenge

The diesel in storage tanks goes through a lot of steps from the refinery to the storage tanks, and along the way, particle content increases, water content increases, and traces from sludge and bacteria can be found in the diesel. If the diesel is not maintained during storage you will consume inline filters on a daily basis and still struggle to keep diesel within specifications. Failure to keep the diesel sufficiently clean and dry will result in failure in fuel pumps, injectors, corrosion and poor fuel economy. High consumption of inline filters and clogging of inline filters will be common. For some generator applications, e.g. back up for hospitals, lives may even be at risk, if the diesel is too contaminated to keep the generator running.

Benefits, installing CJC® Oil Filters

- Extend lifetime of engines and generators with a factor 3-4

- 18,000 hours on injectors

- Reduce inline filter consumption by 80%

- Reduce spare parts consumption by up to 60%

- Protect your investment

- Reduce risk of unplanned breakdowns, repairs and maintenance and get piece of mind

There is a direct correlation between diesel fuel cleanliness, equipment uptime and operating costs. When you install a CJC® Oil Filter solution on your diesel storage tank, you get the oil filter with the highest dirt capacity suitable for the normal service intervals, so that you do not need to change filter inserts on a monthly basis. But more importantly, with CJC® Oil Filtration you keep the diesel dry and therefore guaranteed free from diesel pest/sludge which is a significant problem in terms of diesel cleanliness, inline filter consumption and impact on equipment. CJC® Oil Filtration can help you achieve 18,000 hours on injectors, reduce your consumption of inline filters by up to 80% and help you improve fuel efficiency by around 3%. And you can even monitor from remote the condition of your diesel using the Oil Contamination Monitor (OCM).

Your solutions

For diesel storage tanks the following CJC® System Solutions apply:

- Fine Filters from size HDU 27/108 up to large HDU 27/108 multistay

and HDU 427/- series - Filter Separators, PTU3 Multistay

- Filter Inserts type BLA or FA

- Oil Contamination Monitor, OCM15

The CJC® System Solutions fit all diesel storage tanks regardless of oil volume, and we can deliver globally where required. In close co-operation with technical organizations, we help select the most fitting solution depending on system type and conditions in the environment.